Fuel Polishing

Microbial contamination (diesel bugs) in fuel storage tanks is becoming a major issue. Often the first signs are when generators stop working or pump or vehicle filters block, in some cases resulting in hefty machinery repair bills. The latest fuels contain 7% of bio which provide an ideal breeding ground for these bugs. Biofuel acts as a detergent cleaning the inside of the storage tanks allowing dirt to be sucked up by pumps, blocking filters. Over time these microbes/bugs grow into large colony forming units (CFUs) which get sucked into fuel lines blocking filters.

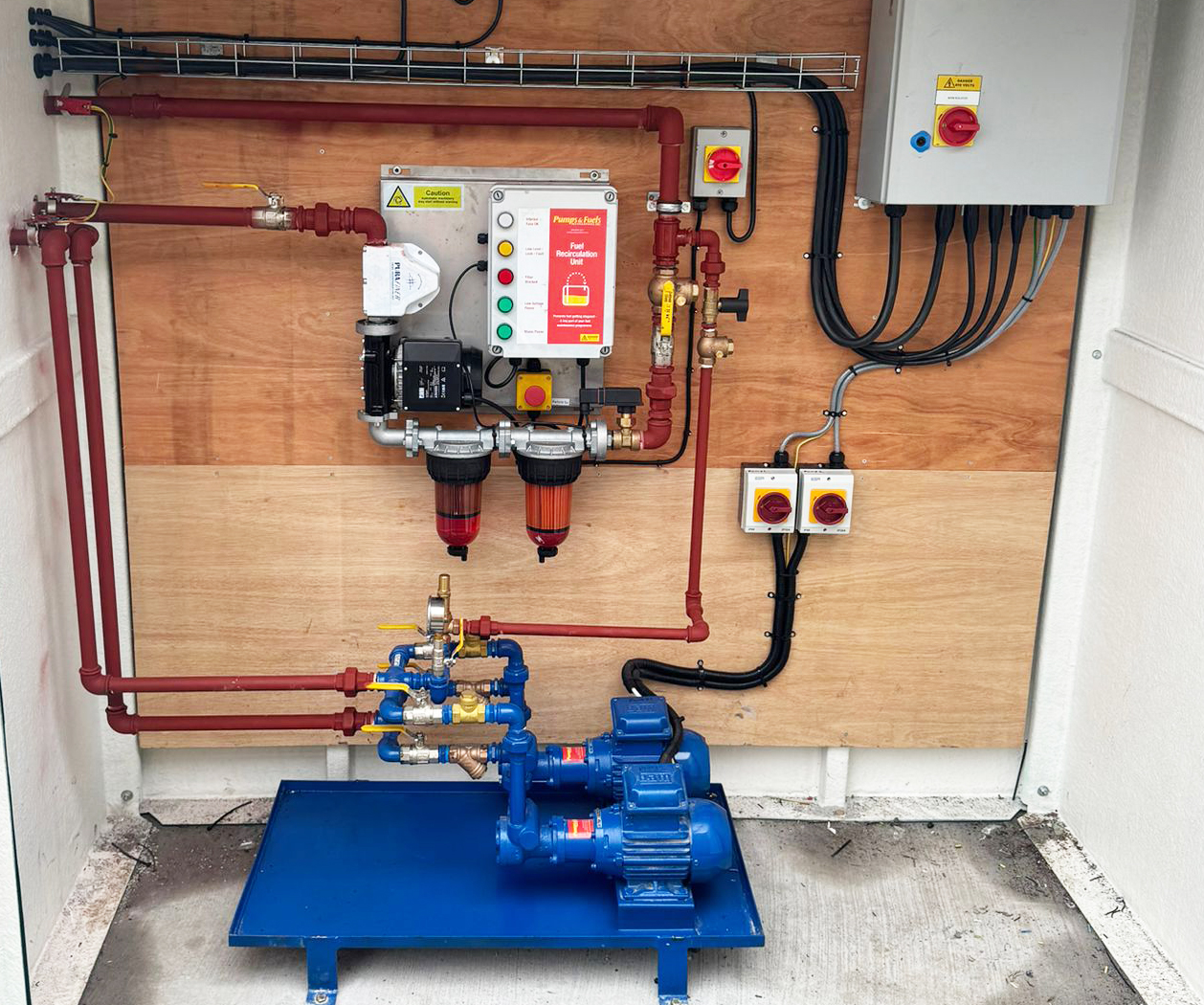

Storage tanks particularly those with low usage require a permanent system to keep the microbes/bugs dormant by re-circulating fuel to ensure effective microbial treatment.

Fuel polishing systems circulate & prevent degradation of fuel inside storage tanks. By recirculating the fuel through a fuel conditioner, this helps prevent microbial growth. Fuel is automatically circulated for a pre-set number of timed periods to ensure the tank contents is re-circulated. When the pump flow rate drops below a pre-set limit (indicating a clogged filter) the flow switch closes & a warning light flashes and sounder with 70 dB rating is activated. This can be linked to a Building Management System. The polishing unit will recirculate fuel from the bottom of the tank to the top of the tank. 220/240 volt single phase electrical supply required.